While unsharpness shows the resolution perpendicular to the x-ray beam, contrast defines the resolution in direction of the beam.

ASTM E1316 (Definitions) defines contrast sensitivity as "

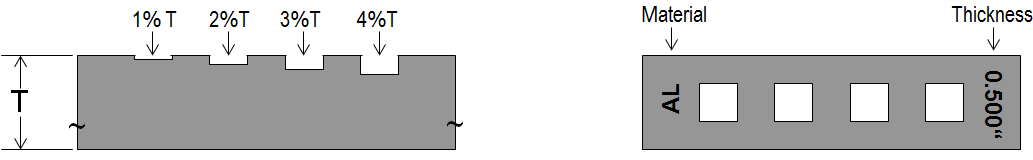

a measure of the minimum percentage change in an object which produces a perceptible density/brightness change in the radiological image". As far as I know there is only one standardized IQI for measurement of the contrast independent of the imaging system spatial resolution limitations: ASTM E1647 with recesses large enough to exclude unsharpness issues:

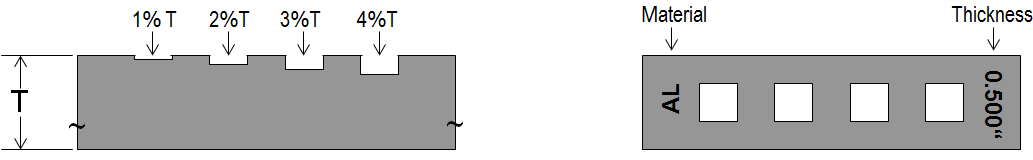

The blocks with the recesses are available in eight different material types and four different sizes. Here is a picture of four of them:

All other IQIs measure contrast and spatial resolution at the same time with the IQI, e.g. hole penetrameter, step-hole penetrameter or wires.

ASTM E1647 (-94:

Standard Practice for Determining Contrast Sensitivity in Radioscopy) is one of the radiocopy standards but since 2003 renamed to

Standard Practice forDetermining Contrast Sensitivity in Radiology and also included in the CR Phantom of ASTM E2445 in the versions of AL, CU and SS.

The evaluation is quite easy: You look at the image and the shallowest recess that can be repeatably and reliably imaged shall determine the limiting contrast sensitivity in [%].

If you need repeatable results you can measure in ROIs with about half of the size of the recess inside the recesses the mean pixel value and substract the mean pixel value of an similar size ROI beside the recess. The result is the absolut contrast of the percentage of the recess. E.g. if you measure 200 PV difference of the 2% recess you have 100 PV for 1% material difference. Alternativly you also could use a line profile function across the four recesses and read the contrast at the scale on the left in absolute PVs.

Normally there is always a 1% contrast in the image measurable but sometimes you can not see the 1% recess. This may happend due to noise in the image. Therefore normally all requiremends are defined in

Contrast to

Noise

Ratio (CNR).

Large object (like the recesses) are visible in the image if their signal is larger than the noise level.

Hint: For small objects - like the holes of the E1025 penetrameters - a CNR of 2.5 is required; this value was valid in the aerospace intustry for years because of a study which was done with a 127µm detector. Different SR

Bs would require different factors - maily smaller for smaller SR

Bs.